Barber Shop Microcontroller Intros (using micro:bits and Arduino Unos)

Mechatronics (Technological Systems 8457 and 8463) Exploring Technological Systems competencies #31-42

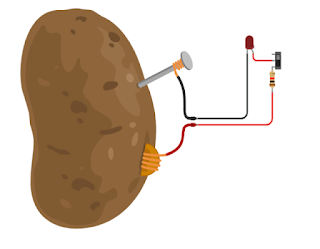

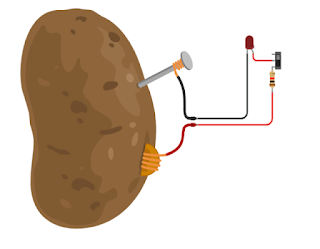

I. Potato Circuit (with Universal Systems explanation)

- Make a circuit that can light an LED on and off (you will need to add an on/off switch), using a potato or several potatoes for power: https://youtu.be/-fvmb4lchnA

- Add more potatoes until it overloads the lightbulb (hover over the lightbulb)

- Experiment with it. Other fruits? Can it make other items “run?” What can you do that’s different than everyone else?

- You will have to explain how it applies to the Universal Systems model at the end.

The Universal Systems Model

The Universal Systems model is a way to understand how things work together to achieve a goal. It has four main parts: inputs, processes, outputs, and feedback. Inputs are the things that go into a system, like people, materials, time, energy, and information. Processes are what happens to the inputs to make them into something new or useful. Outputs are the results of the processes, like a finished product or a service. Feedback is information that tells us how well the system is working and helps us make improvements.

In the Universal Systems model, inputs can be things like resources, knowledge, and tools. For example, when a company makes candy bars, the inputs are the cocoa beans, sugar, and machinery they use to make the bars. Processes are the actions that happen to the inputs to turn them into something new. In the candy bar example, the processes would be mixing the ingredients, shaping the bars, and packaging them. The outputs are the finished candy bars that are then shipped to stores. And feedback could be customer reviews or sales data that tell the company how well its candy bars are doing.

Feedback is important because it helps us make improvements to the system. If we get feedback that something isn't working well, we can make changes to the inputs or processes to get a better output. For example, if people complain that the candy bars are too sweet, the company could adjust the amount of sugar they use in the recipe. Feedback can come from many sources, like customer reviews, surveys, or trends in the market.

So, the Universal Systems model helps us understand how things work together to achieve a goal. It shows us that inputs go through processes to become outputs, and feedback helps us make improvements. It's like a big puzzle where all the pieces fit together to make something great!

Input

There are 7 types of resources that provide input: There are 7 types of resources that provide input:

- People

- Materials - natural, synthetic, raw, industrial

- Tools and machines - measuring, layout, separating, forming, and combining

- Energy - inexhaustible, renewable and nonrenewable (examples - heat, light, sound, chemical, nuclear, mechanical, and electrical)

- Time

- Capital - money, land, structures, and equipment

- Information

Processes

It's what happens to the inputs

- All the activities that need to take place for the system to give the desired result

- A series of actions directed to an end

- The inputs are combined by means of management and production.

- Managing - planning, organizing, and controlling

- Production - the actual making of the product

Outputs

The resulting product of inputs and processes

- Everything that results:

- Intended outputs

- Nonintended - ex. waste (pollution) or changes in society (communicating through e-mails

- Outputs can be:

- Desirable

- Undesirable

- Expected

- Unexpected

- Example: The output of our cleanup system:

- Clean, safe, organized room

- Clouds of dust

- Lost teaching time

- Wear and tear on the equipment

Feedback

The reaction to the inputs, process, and outputs. They serve to reinforce or alter the elements of the system.

- Cleanup example - Feedback - the next class coming into the room, If they complain or trip over equipment left out, the system would have to be improved.

- Feedback becomes an input into the system

Now, you need to apply this system to our Potato Circuit lesson. Explain each of the 4 parts and what they are in your potato. In the end, what is your feedback, and why did I have you watch the second video?

37. Explore the Universal Systems Model.

Exploration should include:

- inputs (e.g., people, materials, time, capital, energy, information)

- processes (e.g., management, production)

- outputs (e.g., intended, unintended)

- feedback (e.g., open-loop, closed-loop).

Process/Skill Questions:

- What is the difference between open- and closed-loop systems?

- How does feedback change the process?

- What is an example of a production process?

38. Analyze a product, process, or system, using the Universal Systems Model.

Analysis should include:

- inputs

- processes

- outputs

- feedback

Process/Skill Questions:

- What are the intended and unintended outputs?

- How does one know if the system is open- or closed-loop?

- How does the product, process, or system convert inputs into outputs?